Three Phase Induction Motor and its Application

1. Squirrel Cage Induction Motor

2. Slip Ring Induction Motor

1. Squirrel Cage Induction Motor

Induction motor is also called asynchronous motor as it runs at a speed other than the synchronous speed. Like any other electrical motor, induction motor have two main parts namely rotor and stator,

The slots of the stator core contain three separate single phase windings. When three currents 120 electrical degrees apart pass through these winding, a rotating magnetic field results. This field travels around the inside of the stator core. The speed of the rotating magnetic field depends on the number of stator poles and the frequency of the power source. This speed is called the synchronous speed and is determined by the formula given below

Synchronous speed RPM = 120 * frequency in hertz / No. of poles

S= 120*f / p

S = Synchronous speed

f = Hertz (frequency)

p = no. of poles per phase

Advantages of Squirrel Cage Induction Motor:

- Squirrel Cage Induction motors are cheaper in cost compared to Slip Ring Induction motors.

- Requires less maintenance and rugged construction. Because of the absence of slip rings, brushes maintenance duration and cost associated with the wear and tear of brushes are minimized

- Squirrel Cage Induction Motors requires less conductor material than slip ring motor, hence copper losses in squirrel cage motors are less results in higher efficiency compared to slip ring induction motor

- Squirrel cage motors are explosion proof due to the absence of brushes slip rings and brushes which eliminates the risks of sparking.

- Squirrel Cage motors are better cooled compared to slip ring induction motors

- Squirrel cage motors operate at nearly constant speed, high over load capacity, and operates at better power factor.

Squirrel Cage Induction Motor Disadvantages:

- Main disadvantage of squirrel cage induction motor is that they have poor starting torque and high starting currents. Starting torque will be in the order of 1.5 to 2 times the full load torque and starting current is as high as 5 to 9 times the full load current. In slip ring induction motors, higher starting torque can be attained by providing an external resistance in the rotor circuits during starting of the slip-ring induction motor. This arrangement in slip-ring induction motors also reduces the high inrush currents during starting of induction motor.

- Squirrel cage induction motors are more sensitive to the supply voltage fluctuations. When the supply voltage is reduced, induction motor draws more current. During voltage surges, increase in voltage saturates the magnetic components of the squirrel cage induction motor.

- Speed control is not possible in squirrel cage induction motor. This is one of the major diadvantages of squirrel cage induction motors.

- The total energy loss during starting of squirrel cage motor is more compared to slip ring motors. This point is significant if the application involves frequent starting

Application

Squirrel cage induction motors are widely used in industrial applications than slip ring induction motors due to cheaper in cost, rugged in construction, low maintenance. Squirrel cage induction motors are suitable for applications where drives requires constant speed, low starting torque.

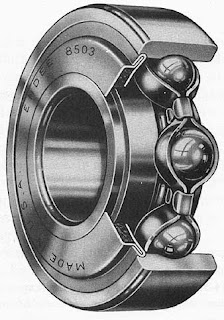

Some Bearing use in Induction Motor

Cross section view of Bearing

Single sealed type Ball Bearing

Double Ball Bearing